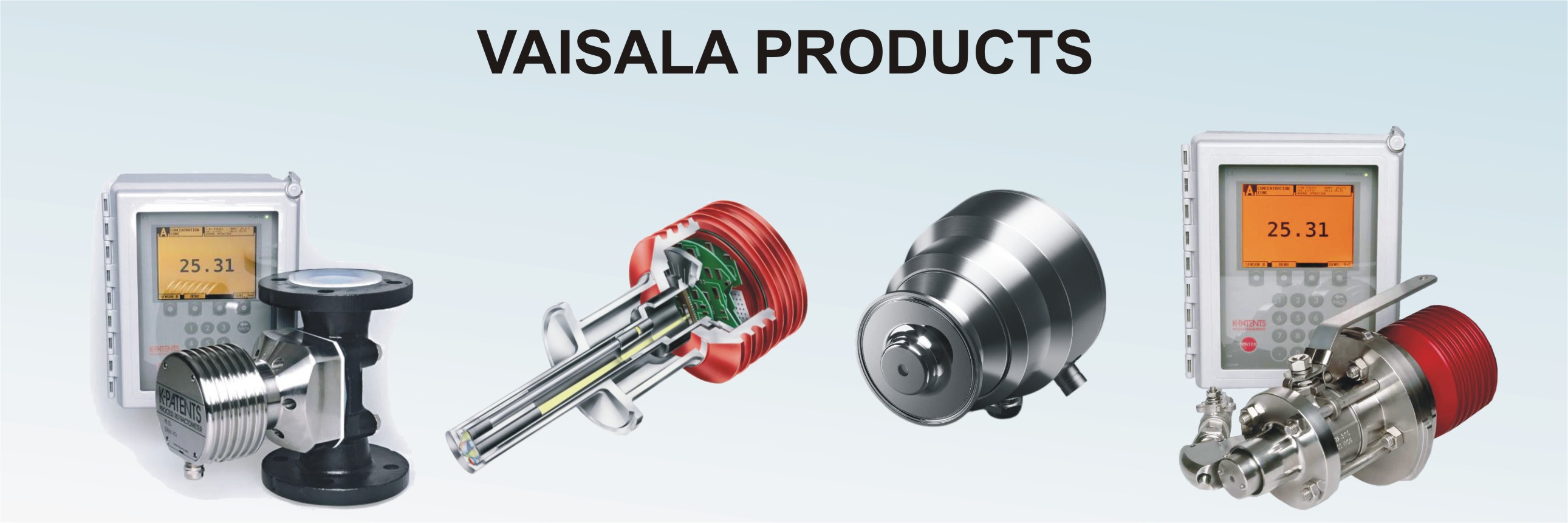

Vaisala K-Patents® Process Refractometers are used for inline liquid measurements to enable efficient process control and industrial automation. Vaisala is a global leader in measurement instruments and intelligence for climate action.

Process refractometers became part of Vaisala in 2019, following the acquisition of K-PATENTS, a leading innovator with over 40 years of experience in designing and manufacturing industrial process refractometers to cater to a wide range of applications.

CSE has been working with K-Patents since 2003 as their exclusive distributor. CSE has installed Process Refractometers in Nestle, Nimir Chemicals and Faruki Pulp Mills. CSE provided NESTLE with their first K-Patents® Refractometer in order to measure the TDS content in their milk products.

It is used for Paper & Pulp Industry, Recovery Boiler, Chemical, Metal & Mining

Vaisala has been recognized in 2025’s first edition of TIME’s “World’s Best Companies Sustainable Growth” study.

FEATURES

-

- Completely digital system from the sensors to the transmitters. The system is completely microprocessor controlled and all analog circuitry has been eliminated.

- Digital signal transmission and microprocessor implemented diagnostics ensure error free operation.

- The system eliminates false alarms, because it reacts only when the level of solids truly falls below the safe limit. By using K-Patents DD-23, costly process disturbances resulting from unwarranted divert actions can be avoided.

- Easy to operate and clear multi-diagnostic messages.

- K-Patents SAFE-DRIVE® isolation and retractor allow for safe and easy insertion and

removal of the refractometer sensor under full process pressure. Easy-to-place and self-retaining design. Triple sealing by two lip seals and an O-ring.

Vaisala K-PATENTS DD-23 system includes two K-Patents SAFE-DRIVE Refractometer PR-23-SD sensors in the main black liquor line, and two Indicating transmitters and a Divert control unit in an integrated panel. Remote monitoring, and event data logging is via Ethernet.

Vaisala K-PATENTS SAFE-DRIVE Process refractometer sensors are installed with SAFE-DRIVE Isolation valve that allows for safe and easy insertion and retraction of the refractometers under full operating pressure without having to valve off the liquor piping or having to shut down the process. The SAFE-DRIVE Isolation valve contains a steam wash system for automatic prism cleaning. The system contains a SAFE-DRIVE Retractor tool SDR-23 for safe sensor insertion and retraction.

Each refractometer is a completely independent measurement system. Each system sends a separate mA output signal, which can be used by a control system or a DCS.

The DD-23 system is completely microprocessor controlled. The digital signal transmission and microprocessor implemented diagnostics ensure error free operation

Vaisala Polaris™ PR53AC and ACEX Sanitary Compact Process Refractometers for ordinary and Explosive Areas

Measure Brix and other liquid concentrations with instant productivity and material gains, and simplified process operation for food, beverage, dairy, and brewery manufacturing

By choosing Vaisala Polaris PR53AC sanitary compact process refractometer you get a reliable, modern and modular product platform that is safe to use in food and beverage manufacturing, has 3-A Sanitary and EHEDG certifications and meets all hygienic demands.

The product works in every process condition from stable to demanding, in high process temperatures, and in sticky processes. It is also compatible with clean-in-place (CIP) and sanitation-in-place (SIP) systems. Connectivity options include mA, HART, and Modbus RTU as a standard.

KEY BENEFITS

3-A Sanitary and EHEDG Certified

Hygienic certification guarantees that all hygienic demands are met, and sanitary features are woven into the product design. The product is safe and suitable to use in food and beverage processing.

Full Measurement Range

The measurement range for concentration/Brix is 0-100 %.

Always Accurate, No Drift

The measurement is based on optical measurement of the refractive index (RI). The RI can be measured from practically any liquid or slurry, and it is sensitive to dissolved material. Particles, bubbles or color do not affect the measurement.

Outstanding Durability

The outstanding long-term stability and the measurement principle with no moving parts provides years, even decades of accurate, continuous, fast and stable measurement for concentration of sugar (Brix) and various other chemical concentrations directly in the process stream.

Customizable

Product With Our Engineer To Order Service

In

addition to wide standard process connection offering, Vaisala offers an

opportunity to customize the product to meet specific processing needs whether

it is a wetted parts material, custom size process connections or custom type

enclosure for transmitters (Ex d/Ex p).

Easy

Installation, Easy and Low Maintenance

Process

refractometers are easy to install and low maintenance instruments. The optical

measurement principle combined with an instrument with zero moving parts does

not require regular maintenance.