NT6000 DCS

The NT6000 Intelligent DCS is safe, controllable and highly intelligent, and can be widely used in electric power, nuclear power, petrochemical, metallurgy and other fields to provide more advanced and safer control. Both DCS system research and development, design, production and service capabilities, has been applied to more than 30,000 sets, in the field of coal-fired power generation, gas turbine power generation, waste power generation, waste heat power generation and biomass power generation

Features

- Easy on the outside

- Robust at the core

- Unlimited speed

- Precise control

- Digital connectivity

- Information presentation

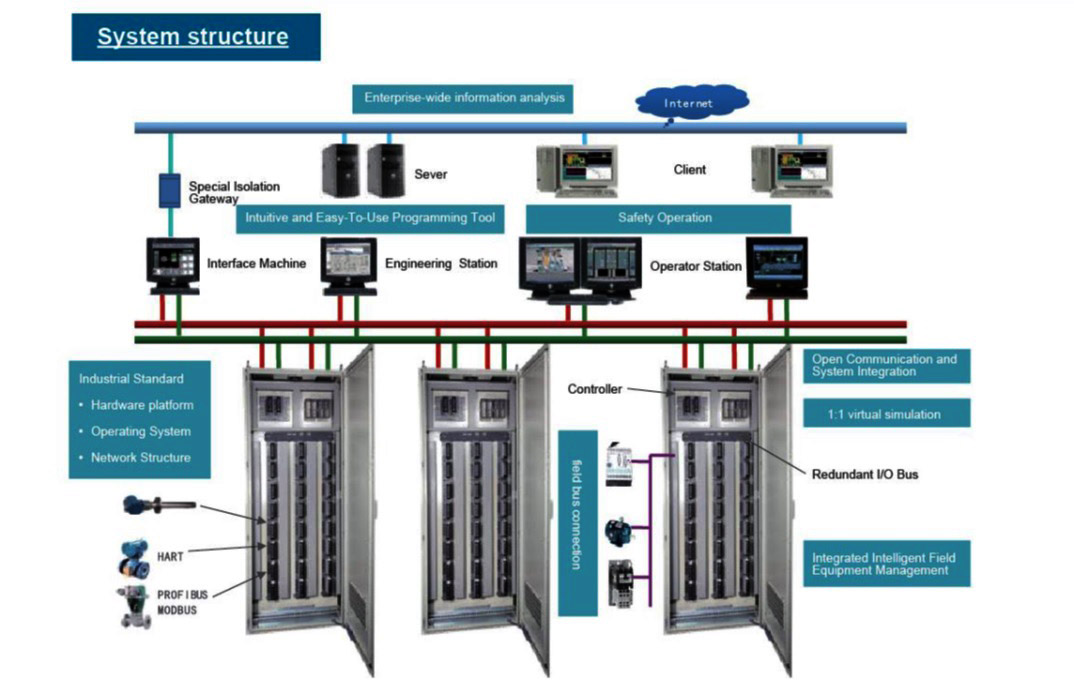

System Features

The hardware is completely self-supporting

All electronic components utilized in the NT6000 system’s hardware — including redundant controllers, general-purpose DCS I/O modules, DEH-specific modules, network communication interface modules, and cabinet assemblies— are manufactured by mainland Chinese suppliers. Within the new fully localized and independently controllable NT6000 DCS, the operating systems for host devices such as engineering stations and operator stations run on domestic CPU hardware platforms

The software is completely independently developed and own 100% source code

In the new fully localized and self-supporting NT6000 system, all embedded operating systems are self-supporting, embedded real-time operating systems based on open-source technology. The source code of these real-time operating systems has undergone thorough auditing, with supported systems including Linux and FreeRTOS. The DCS embedded software is exclusively developed by Sciyon. The company possesses full source code ownership, holds independent intellectual property rights, and the system is free from third-party intellectual property dependencies.

Intelligent Control Network

Based on the DCS real-time control network, an advanced application service network is built, and the deep integration of intelligent control and conventional control is achieved by deploying high-performance servers, large real-time/historical databases, intelligent production cloud controller servers and other components.

ELECTRIC ACTUATOR

STARFISH INTELLIGENT ELECTRIC ACTUATOR

The product of the S series-STARFISH Intelligent Electric Actuator is developed independently and designed innovatively by SCIYON. It has combined with over two decades of experience in the Automation industry, and has assimilated characteristics of domestic and foreign actuators. The product was launched in 2008 and has been widely used in fields such as electric power, petroleum, papermaking, chemical industry, steel industry, cement, and water treatment, and the sales are at the top of rankings in the areas of Intelligent electric actuator sales.

Unique design

The Display Orientation is Adjustable

STARFISH actuator display main interface supports 0° and 180° display directions, which can be configured. For installation operation, a more flexible and more comfortable operation.

Rich Diagnostic Information

People learn things through information, and users know the status of equipment through information from actuators. The STARFISH actuator is directed by text through the OLED dot matrix screen. The user presents the signal acquisition status of the actuator, displays the operation information such as the number of switches and the length of time, and describes the torque curve in the process of switching the valve with graphics.

The pressure in the transmission chamber is automatically adjusted

STARFISH products adopt the unique transmission cavity pressure self-adjustment

technology, which can automatically release the pressure when the internal pressure of the transmission cavity rises due to the increase in temperature during the working process, ensuring the relatively low pressure state in the cavity and the reliability of the seal, so that the lubrication effect of the transmission parts is effective for a long time. Thanks to this technology, seals do not need to be replaced throughout the entire product life cycle, making them simple, reliable and maintenance-free.

Aircraft Porthole Design

It adopts a double-layer display window design similar to an aircraft porthole, with a temperature insulation layer in the middle, and the change of the external ambient

Electronic Combination Lock

The traditional actuator often adopts the mechanical lock to prevent the mode state from being misoperated, and the Keyuan actuator adds an electronic code lock to prevent misoperation on the basis of the mechanical lock. When switching the state, you need to enter the password to complete the mode switch. The password can be configured by the user.

High-precision valve position signal acquisition

The high-precision encoder is selected, and the encoder directly collects the output shaft without intermediate transmission. In addition, the connection between the encoder and the output shaft adopts 0 gap transmission to eliminate sampling errors and ensure acquisition accuracy.