VARIABLE AREA FLOW METER

Variable area (VA) flowmeter for flow measurement of liquids and gases. The all-purpose flowmeter is suitable for all basic applications up to +100°C / +212°F and max. 10 bar / 145 psi. Typical applications include flow measurement of flushing, purging or inert gases or heating and cooling circuits.

Variable area flowmeter for basic applications

- With glass tube, MIN/MAX switches and 4…20 mA

- Low pressure loss for gas applications

- Flange: DN15…50 / ½…2″; also NPT, G, hygienic connections, etc.

- -20…+100°C / -4…+212°F; max. 10 bar / 145 psig

VARIABLE AREA FLOWMETER FOR LIQUIDS AND GASES

VARIABLE AREA FLOWMETER FOR LIQUIDS AND GASES

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in descending pipes

- Flange: DN15…150 / ½…6″; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

The H250 M40 is the standard variable area (VA) flowmeter for the process and OEM industry. The VA meter combines mechanical flow measurement of liquids or gases with state-of-the-art communication capabilities. The device is modularly extendable. Additional electronic modules can be added or replaced at any time without process interruption. In this way, its functionality adapts to new requirements – from analogue flow measurement without auxiliary power to digital integration into a fieldbus system.

ELECTROMAGNETIC FLOW METER

The Electromagnetic Flowmeter (EMF) is developed in accordance with IEC 61508 for safety-related applications up to Safety Integrity Level (SIL) 2/3. It features automated partial proof testing capabilities, which allows to extend the time interval between full proof tests and increase plant uptime in safety instrumented systems (SIS).

Electromagnetic flowmeter for safety instrumented systems (SIS) and high-accuracy requirements

- Certified for safety applications up to SIL 2/3, with automated partial proof test capability for extended proof test intervals

- Best-in-class diagnostic test interval incl. fault response time of only 2 minutes

- SIL 2/3 up to DN600 / 24″; non-SIL up to DN2000 / 80″ (larger on request)

- Pulse, frequency, status, 4…20 mA, HART®7

OPTIFLUX 1050 / 1100

Electromagnetic Flowmeter for basic applications with Conductive Liquids

- Cost-effective flow measurement of liquids (≥5 μS/cm) up to +120°C / +248°F

- Extra isolation of electronics for use in high humidity areas

- Wafer-style design: DN10…150 / ⅜…6″, max. PN40 / ASME Cl 300

4…20 mA, pulse, frequency, status, HART®, Modbus

Electromagnetic Water Meter for District Metering of Potable Water and Custody Transfer (Ct) Measurement

- Battery- or mains powered, with battery backup option (incl. Modbus)

- Integrated temperature and pressure measurement for leak monitoring

- CT: MI-001, OIML R49 up to DN600 / 24″, no inlet/outlet runs needed

- Burial installation possible (IP68)

WATERFLUX 3070

OPTIFLUX 2300

Electromagnetic Flowmeter for Advanced Water and Wastewater Applications

- High accuracy (±0.2%), with CT approvals (OIML R49, MI-001)

- 0D/0D installation acc. to MID MI-001 and OIML R49 accuracy class 1

- Flange: DN25…3000 / 1…120″, max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP, PROFINET

Electromagnetic Flowmeter for OEM applications, Dosing Systems and Compact Skids

- Economical flow measurement of liquids (≥5 μS/cm) with solid content (≤70%)

- -25…+120°C / -13…+248°F

- Wafer-style design: DN10…150 / ⅜…6″, max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP, PROFINE

OPTIFLUX 1300

WATERFLUX 3100

Electromagnetic Flowmeter for Standard Water Applications

- From raw water measurement to drinking water metering in distribution networks

- No inlet/outlet runs needed

- Up to DN600 / 24″, max. PN16 / ASME Cl 150

- 4…20 mA, pulse, frequency, status, HART®

Electromagnetic Flowmeter for Advanced Process & Custody Transfer (CT) Applications

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120″, max. PN40 / ASME Cl 600 (higher on request)

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

OPTIFLUX 4300

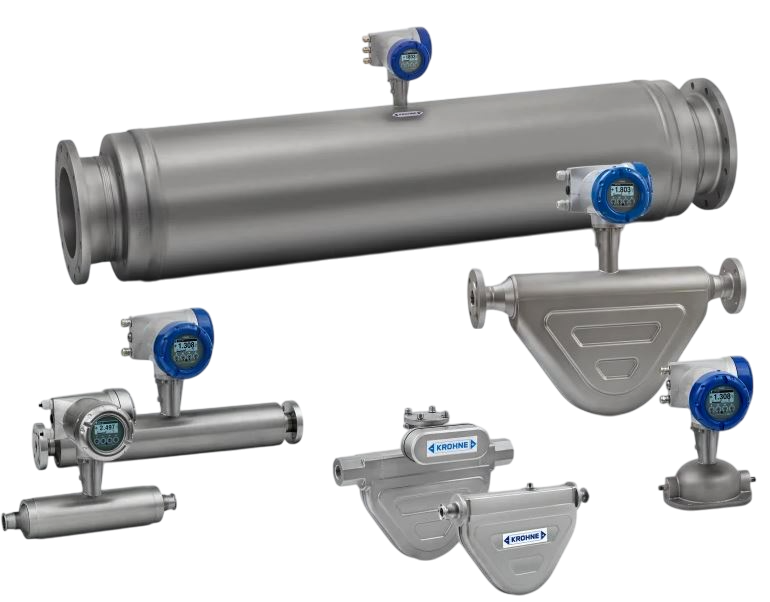

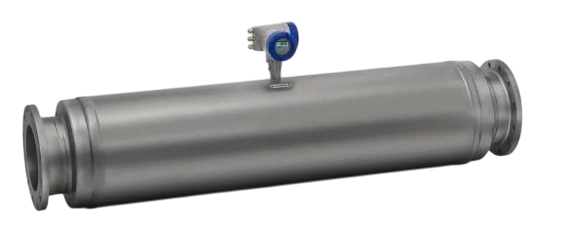

MASS FLOW METER

The function of Mass Flowmeters is based on the Coriolis principle. They allow for a direct measurement of mass flow, density and temperature of liquids and gases as well as calculation of volume Flow and Mass or volume Concentration with a Single Device

Typical applications include:

- Chemical: measurement of concentration or density, bulk loading, batching to reactors, hydrocarbon cracking, aggressive, abrasive or viscous media or media of unknown composition

- Food & beverage: filling machine applications, measurement of degrees Brix, flow, density, specific gravity, and additive components dosing

- Pharmaceutical: batching, dosing and filling, solvent extraction ultra-pure water measurement

- Water & wastewater: flocculent dosing, sludge flow and density measurement

- Pulp & paper: paper stock, pulp, additives, bleaches, colourants

- Oil & gas: metering skids, bypass density measurement,

CNG/LPG dispensers, leak detection, custody transfer applications such as tanker loading, bunkering and pipeline transfer

OPTIMASS 6400

Coriolis mass Flowmeter for Advanced Process Applications

- High accuracy (±0.05% flat), for cryogenic to high temperature media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12″, max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, PROFINET (Ethernet-APL), EtherNet/IP™, Bluetooth®

Coriolis Mass Flowmeter for Advanced Process Applications

- High accuracy (±0.1%), for viscous, aggressive or shear-sensitive media; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005; API; hygienic certifications

- Flange: DN10…100 / ½…4″, max. PN100 / ASME Cl 600; others

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, PROFINET (Ethernet-APL), EtherNet/IP™, Bluetooth®

OPTIMASS 7400

OPTIMASS 2400

Coriolis Mass Flowmeter for the Highest Capacity Bulk Measurement

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16″, max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Coriolis Mass Flowmeter for Universal Applications and Process Control

- Mass, density and volume flow of gases and liquids; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- Also certified for hygienic use

- Flange: DN15…100 / ½…4″, max. PN100 / ASME Cl 600; many hygienic fittings

- 3 x 4…20 mA, HART®7, FF, Profibus-PA/DP, Modbus, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 1400

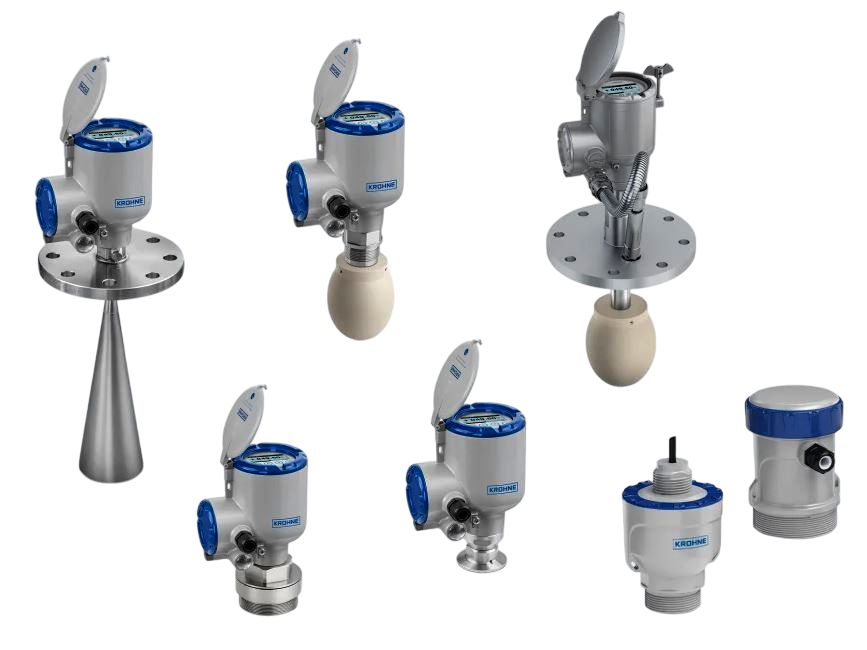

LEVEL TRANSMITTERS

KROHNE Level Transmitters are Industrial Instruments used to measure the Level of Liquids, Slurries, or Bulk Solids in Tanks and Process Vessels. They come in several technologies—such as Ultrasonic, Guided Radar (TDR), Non-contact Radar, and Differential Pressure—allowing reliable measurement in a wide range of applications, including corrosive, High-Pressure, or High-Temperature Environments. KROHNE Transmitters are known for high accuracy, robust construction, easy integration with control systems, and minimal maintenance requirements.

For Continuous Level and Interface Measurement – Contact and Non-Contact

- Various technologies: FMCW Radar, TDR Guided Radar, Ultrasonic, Displacer, Potentiometric, Hydrostatic Pressure

- For Process and Storage applications with Liquids and Solids

- Meet the requirements of various Industries

Non-contact Level Measurement of Liquids, Pastes, Granulates, Powders and other Solids

- Measuring distances up to 100 m / 328 ft

- Different antenna options, e.g. for corrosive or abrasive media, high pressure or temperature and applications with agitators

- Also suitable for hazardous areas, Functional Safety (SIL) or hygienic applications

OPTIWAVE 3500 for liquids with hygienic requirements

OPTIWAVE 5400 for liquids in standard process applications

OPTIWAVE 6400 for advanced applications with solids from granulates to rocks

OPTIWAVE 6500 for advanced applications with powders

OPTIWAVE 7400 for advanced applications with agitated and corrosive liquids

OPTIWAVE 7500 for advanced applications with liquids in narrow tanks with internal obstructions

Radar level transmitters

Guided Radar (TDR) Level Transmitters

Contact Level Measurement of Liquids, Solids or Liquid-Liquid Interfaces

- Measuring distances up to 60 m / 196 ft

- Large choice of probes, e.g. for aggressive or abrasive media, high pressure or temperature and tanks with internals or boiling product surfaces

- Suitable for hazardous areas, Functional Safety (SIL) or hygienic applications

OPTIPLEX 1100 Guided Radar (TDR) Level Transmitter for Basic Liquid Applications

OPTIPLEX 7200 Guided Radar (TDR) Level Transmitter for Advanced Liquid Applications

OPTIPLEX 8200 Guided Radar (TDR) Level Transmitter for Liquids At High Temperature and Pressure

OPTIPLEX 6200 Guided Radar (TDR) Level Transmitter for Solids from Granulates to Powders

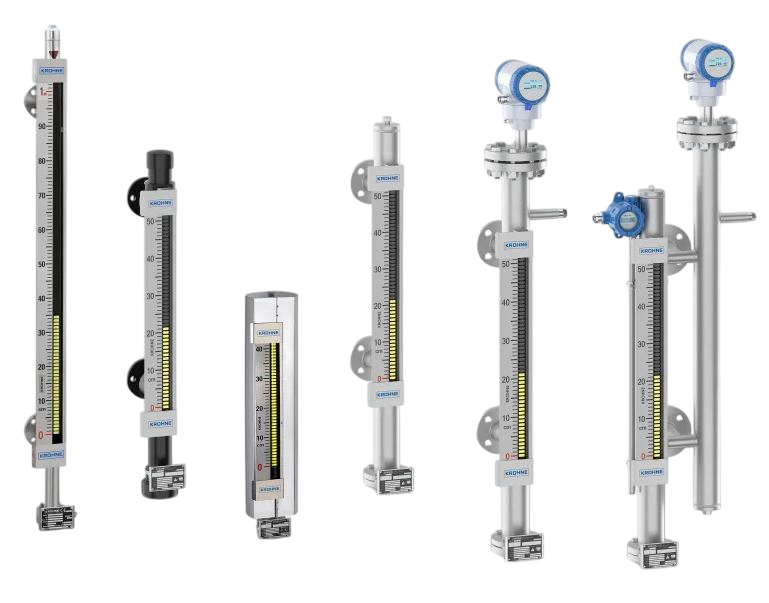

Liquid Level or Interface Indication without Power Supply

- Magnetic float level gauges for an extensive range of applications in all industries

- Rugged metallic design, flaps housed in hermetically sealed glass tube (IP68), no maintenance

- Measuring ranges from 0.3 m / 1 ft to 5.5 m / 18 ft (other dimensions on request)

- BM26A-1000 for basic liquid applications

- BM26A-3000 for corrosive liquids

- BM26A-6000 for liquefied gas

- BM26A-7000 for extreme operating conditions

- BM26A-8000 Magnetic level indicator with level transmitter for liquids in redundant measurement

Magnetic Level Indicators

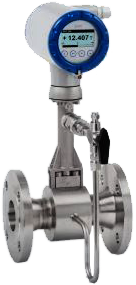

VORTEX FLOWMETER

KROHNE Vortex Flow Meters are advanced, high-precision instruments designed for reliable measurement of liquids, gases, and steam in industrial applications. Vortex Flow Meters provide accurate and stable flow readings without any moving parts, making them exceptionally durable and maintenance-friendly.

Engineered with robust stainless-steel construction and innovative signal-processing technology, KROHNE Vortex Flow Meters offer excellent performance even in demanding operating conditions, such as high temperatures, fluctuating pressures, and challenging process environments. Many models also feature integrated temperature and pressure compensation, enabling direct mass flow and energy (steam/hot water) measurement—ideal for modern energy management and process optimization.

Whether used in power plants, chemical facilities, HVAC systems, or utility services, KROHNE Vortex Flow Meters deliver long-term reliability, low ownership cost, and trusted measurement accuracy across a wide range of industrial applications.

Vortex Flowmeter for Utility Applications and Energy Management Systems

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, normalised flow, energy, gross/net heat

- Flange: DN15…300 / ½…12″; wafer version: max. DN100 / 4″

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

OPTISWIRL 4200

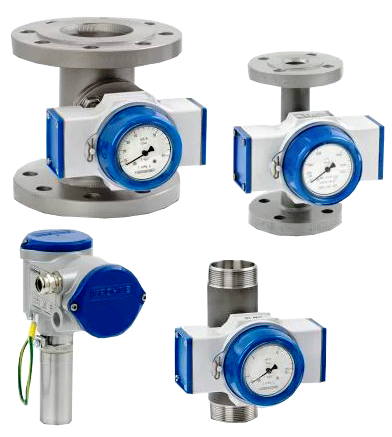

FLOW SWITCHES

For Flow Indication of Conductive & NON-Conductive Liquids

Electromagnetic or Mechanical Measuring Principles

For flow indication of conductive media

Electromagnetic flow switch for flow monitoring of conductive media

2-wire flow switch for liquids, pastes, slurries (≥20μS/cm); also for hygienic use and immersed applications (IP68)

- -25…+150°C / -13…+302°F; max. 25 barg / 360 psig

- For pipes DN25…400 / 1…16″, optional for >DN400 / 16″

For AC and DC electric circuits

Mechanical Flow Switch

- Cost-effective mechanical measuring principle

- No power supply needed

- Suitable for hazardous environments